As electric vehicles continue to dominate global markets, balancing charging efficiency and safety has become a critical challenge in battery design. Valeo has partnered with TotalEnergies to develop a new fireproof battery coolant, marking a major breakthrough in EV thermal management. This coolant can come into direct contact—or even full immersion—with the battery module without posing risks of conductivity, short circuits, or fire. Traditional coolants, if leaked into the battery, can easily trigger short circuits or thermal runaway. By contrast, this new formula has exceptionally low conductivity, is organic and recyclable, and enables more efficient temperature control—helping batteries withstand the heat generated during fast DC charging. Moreover, its immersion cooling design eliminates the need for secondary cooling loops, simplifying the system and lowering costs. Although the fluid’s higher density slightly increases overall weight, Valeo projects a 10-year service life, with the potential to become a lifetime-fill coolant—an innovation that could redefine EV thermal design.

Since its debut in 2012, Valeo’s AquaBlade “wet wiper” system has evolved into a software-defined component. The latest version integrates nozzles on both sides of the rubber blade, allowing the system to determine the spray direction via software control. Two new programs—Clean4U Defrost and Clean4U Debug—can be added through over-the-air (OTA) updates. The Defrost mode activates on cold mornings, moving the wiper upward in small increments while spraying heated fluid, significantly reducing defrosting time when paired with the windshield heating system. The Debug mode targets the common summer issue of insect residue; when the car is parked, it automatically sprays cleaning fluid to dissolve and remove debris for a clearer view. The Defrost feature is already available on select Mercedes-Benz models, and both functions can be added to vehicles equipped with AquaBlade technology through software upgrades—enhancing driver visibility and ensuring ADAS sensors remain clean and accurate.

With the rise of the Software-Defined Vehicle (SDV), Valeo showcased several prototype electronic architectures emphasizing the importance of modular expansion and computational flexibility. One such concept featured an Ethernet-connected modular system that allows additional central or zonal computing units to be plugged in to support future features or heavier processing loads. In a demonstration, when the main computing module reached near-maximum capacity, a secondary unit automatically shared the load. If one module failed, middleware immediately reallocated critical functions to the working unit, maintaining a “fail operational” state. Another concept adopted a “plug-in card” design, enabling automakers to scale processing power as easily as upgrading a motherboard. This modularity allows carmakers to build entry-level and high-end variants on the same architecture, optimizing costs while preserving performance differentiation.

As ADAS and rearview camera resolutions continue to increase, maintaining stable long-term focus has become a challenge. Valeo’s seventh-generation ADAS camera introduces a solid-state “auto-focus” system using MEMS (Micro-Electro-Mechanical Systems)—similar to those in LiDAR sensors—to adjust mirror positions by just 50 microns. This small movement is sufficient to correct optical drift caused by vibration or thermal cycling. Unlike mechanical lens systems, MEMS focusing requires no bulky components, making it simpler, more reliable, and more cost-effective while preserving imaging precision over time. This innovation is expected to become standard for next-generation high-resolution vehicle cameras.

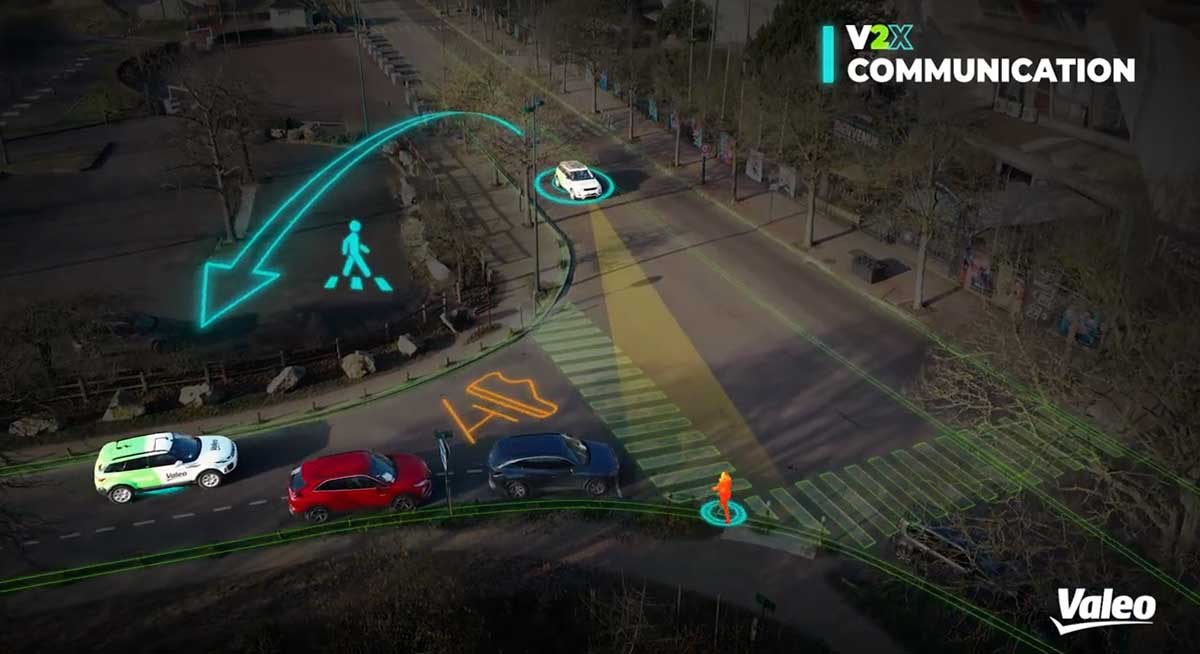

Although vehicle-to-everything (V2X) communication has been discussed for nearly two decades, its real-world adoption has been slow. Valeo’s latest 5G-V2X pedestrian protection system, co-developed with Verizon, brings the concept closer to reality. The system can detect vulnerable road users (VRUs)—such as cyclists, pedestrians, and children—via vehicle sensors, smart intersection cameras, or directly from wearable devices. When integrated with Verizon’s Hyper Precise Location technology and RTK (Real-Time Kinetics) positioning, GPS accuracy improves from meter-level to centimeter-level. When the system identifies a nearby VRU, it can instantly display warnings on the dashboard or trigger automatic braking or evasive maneuvers. Valeo also presented a new flat smart antenna system, which could replace traditional “shark-fin” designs and support non-terrestrial network (NTN) satellite communications—paving the way for next-generation IoT and vehicle connectivity.

In summary, Valeo’s latest innovations not only highlight its technological strength but also reflect the automotive industry’s entry into a new era of hardware-software convergence. From fluid cooling to software upgrades, from electronic architectures to advanced sensing algorithms, each development centers on three key principles—safety, efficiency, and continuous evolution. Collectively, these breakthroughs are poised to accelerate the transformation and application of automotive technologies in the years ahead.