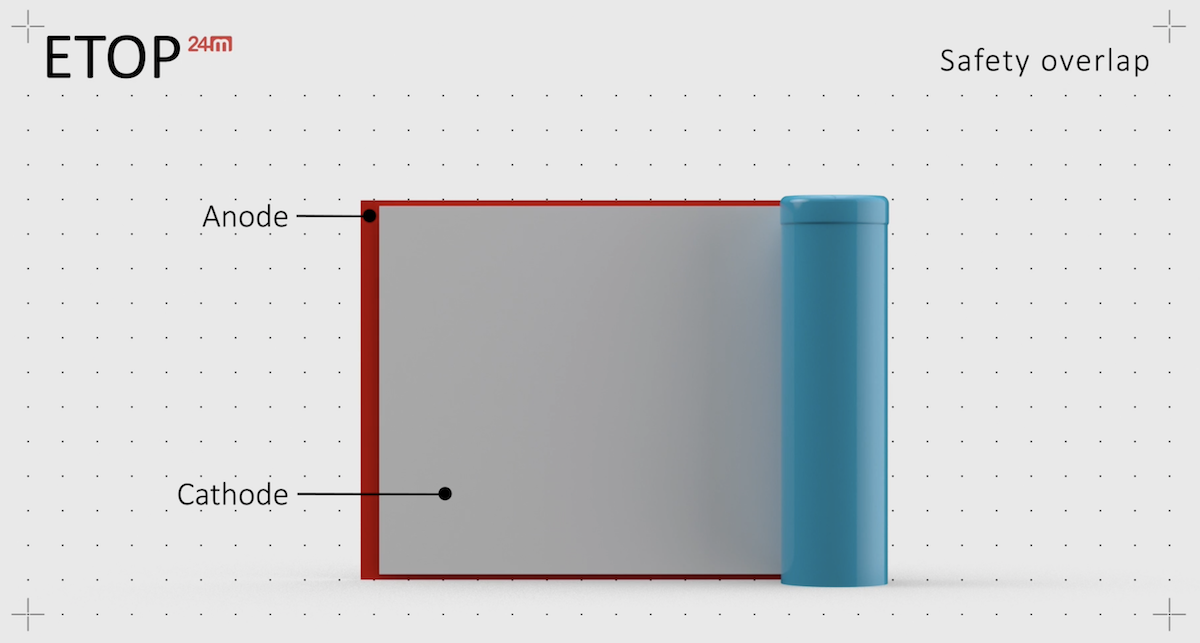

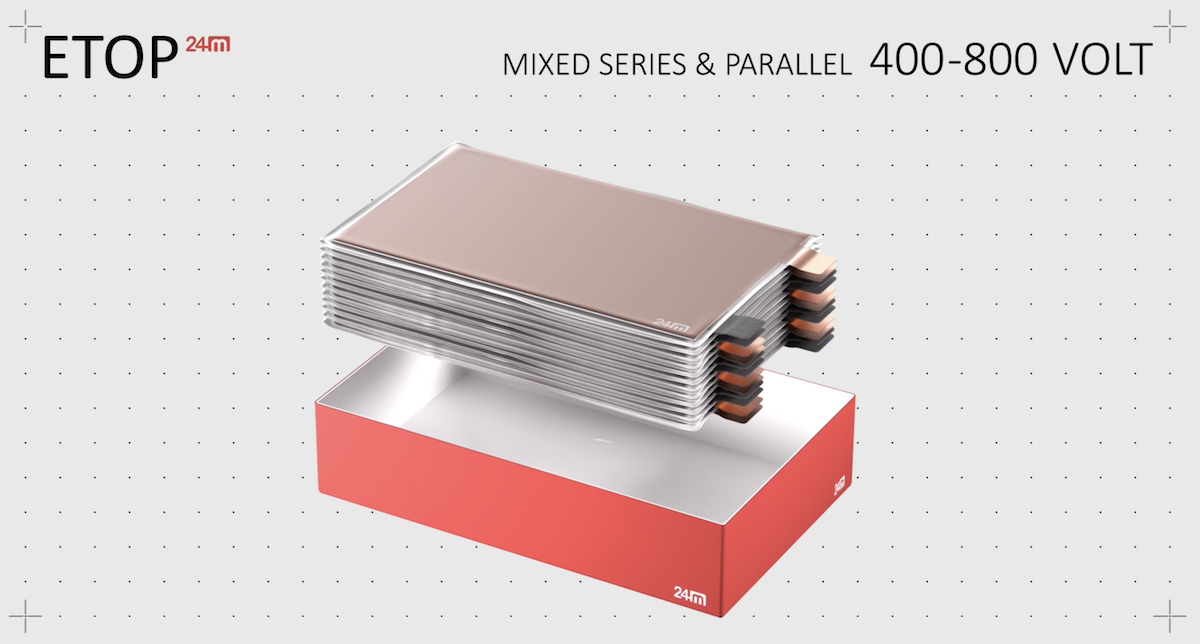

Most of today’s EV batteries use a “layered” structure. First, independent small cells are manufactured, each with its own casing and protective materials. These are then grouped into modules, which are finally stacked into a battery pack. While this approach is safe and proven, it is inefficient. According to 24M, only 30% to 60% of a traditional battery pack’s volume is actually used for energy storage, with the rest taken up by packaging. Even the newer Cell-to-Pack architecture, which has improved some of this wasted space, has not completely solved the problem.

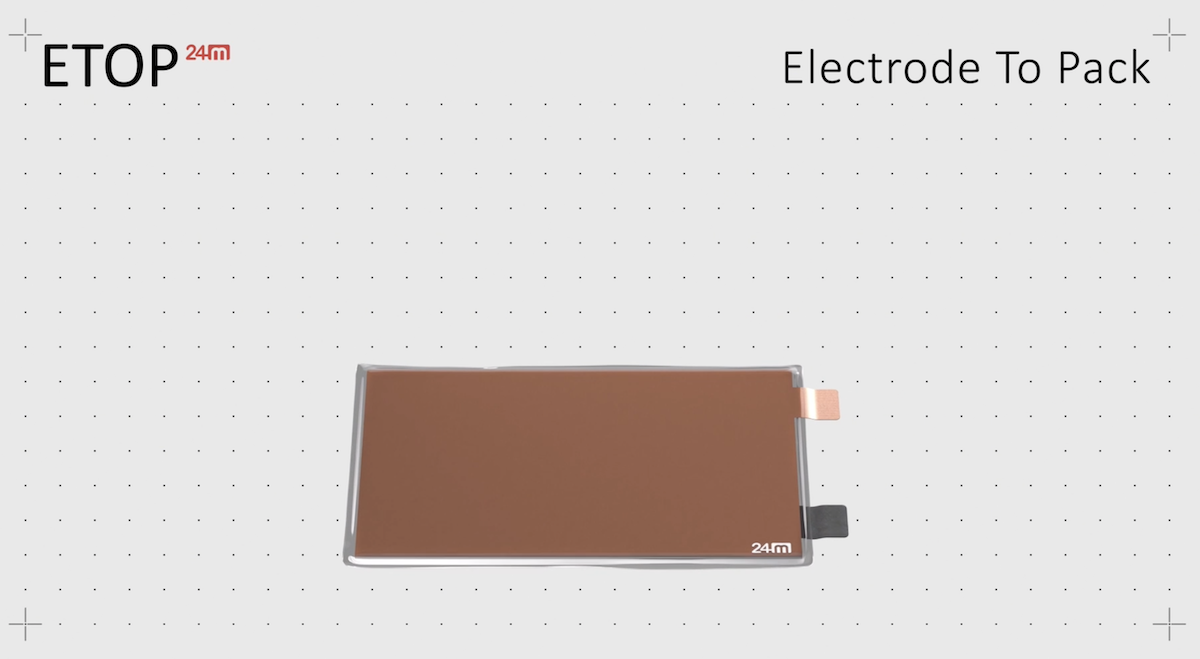

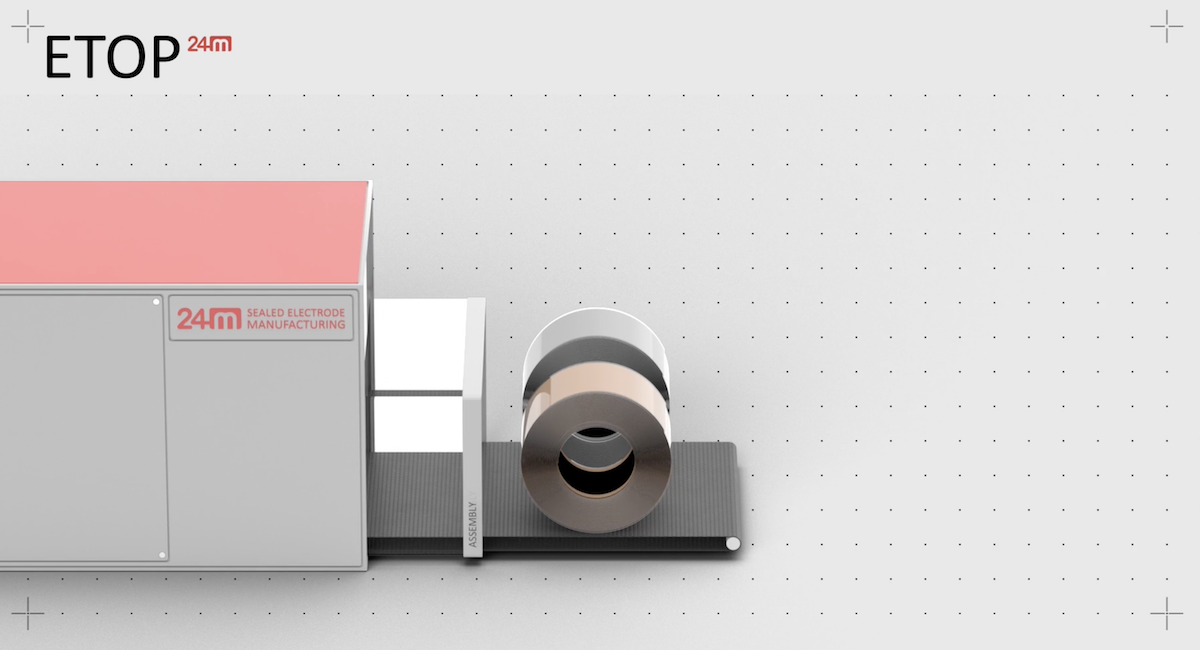

The core of 24M’s ETOP lies in eliminating multiple casings and module structures. Electrode materials are directly sealed in thin polymer films and stacked into the battery pack, without the need for extra metal housings or module frames. As a result, energy utilization can reach up to 80%, significantly higher than traditional designs. This means more energy can be stored in the same volume, leading to higher energy density, longer driving ranges, or smaller and cheaper battery packs.

The so-called “SemiSolid” does not refer to the physical state of the battery but rather to its manufacturing process. This process eliminates the need for binders and drying agents, instead using a clay-like semi-solid electrode material that can incorporate more active material. At the same time, 24M has developed a proprietary electrolyte called “Eternalyte,”which offers high ionic conductivity and supports multiple cathode chemistries. The company claims it enables recharging for 200 miles (about 322 km) of range in under four minutes and maintains performance even at -40°C. As for the Impervio separator, its three-layer design is said to suppress the formation of metal dendrites, thereby reducing the risks of short circuits and fires.

If 24M’s technology proves as effective as claimed, the implications for EVs could be significant. A standard 75 kWh battery pack could be expanded to hold over 100 kWh, representing a direct range increase of 33% to 50%. Automakers could also switch to safer, cheaper chemistries like LFP (lithium-iron phosphate) while maintaining today’s range levels. In addition, the electrode films can be cut into different shapes, making use of irregular spaces within the vehicle body to further enhance passenger and cargo room. For manufacturers, the process could be simplified, reducing the need for precision steps, while improving yields and consistency.

The potential applications of this technology extend beyond electric cars. Electric aircraft and drones could take advantage of additional space for more energy materials, and hybrid vehicles could more easily adapt to 48V systems. If 800V fast charging can be realized, it would also represent a major advancement for high-speed charging networks, further reducing consumer concerns about charging times.

However, all of this is still based on laboratory data. There is a lack of third-party expert verification, the challenges of large-scale production remain unclear, and there is insufficient long-term data on durability and safety. In the battery industry, moving from a technological breakthrough to commercialization often takes years, if not more than a decade. Whether 24M can truly reach the finish line remains to be seen.

In summary, if 24M’s ETOP and SemiSolid technologies deliver on their promises, they could simultaneously address the three major pain points of the EV industry: range, charging speed, and cost. For consumers, this could mean EVs that are cheaper, more durable, and faster to charge. For the industry, it could spark a new wave of innovation in design and supply chains.